- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

Capital Aluminium Extrusions Ltd

Overview

| Today 09:00 AM - 05:30 PM (Currently Closed) |

|

Tel:

01946 811771

Fax:

01946 813681

|

Products

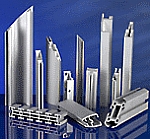

Capital Aluminium Extrusions (Capalex) Ltd is a leading manufacturer of complex, high-tolerance aluminium extrusions in a wide range of commercial alloys. We also offer first class fabrication and assembly services which are made possible by our extensive array of state-of-the-art machining and powder coating equipment.

Thanks to the skills and experience of our engineers and the high precision capabilities offered by our manufacturing plant, we’re able to extrude special aluminium sections and profiles that weigh as little at 0.012kgm, with walls as thin as 0.5mm. A diverse range of standard profile extrusions are also offered, with everything from square bars and channels to rectangular tube and Z sections available within two weeks of ordering.

All of our processes - including extrusion, profiling, fabrication, powder coating and machining - are undertaken at our very own manufacturing plant in Cumbria. That way we can monitor components for quality at all stages of production.

Capalex can also offer fully integrated design services for customers who require assistance in the development of bespoke, application-specific extrusions. Many development engineers, particularly those in the aerospace industry, have found that our design, research and development services provide an invaluable solution for prototyping and ‘one-offs’. We are particularly flexible in that we make no minimal order impositions.

Customers all over the globe now look to Capalex for a fast, cost-effective and high quality service. They include huge multi-nationals right down to one-man engineering shops within the aerospace, architectural, automotive, defence, electronics, engineering, marine, product design, retail and rail industries.

So for complete solutions to your aluminium extrusion requirements, think Capalex. Visit our website today to find out more about the services that we provide, or get in touch with the Capalex team via telephone to discuss your requirements.

Extrusion

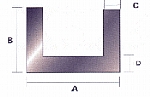

The aluminium extrusion process is used to produce solid sections, profiles, bars, tubes and hollow sections in various shapes and sizes. There are two main methods of extrusion; direct and indirect, both of which are utilised by our engineers in order to accommodate for the varying needs/requirements of our customers. You can find out more about each of these processes by visiting the Capalex website at www.capalex.co.uk. If you would like information and advice regarding the most suitable method for your application, please get in touch with the Capalex team on 01946 811771.

Machining & Fabrication

We are able to provide comprehensive subcontract CNC machining services thanks to the extensive array of equipment that we have at our disposal. This enables us to convert raw lengths of aluminium extrusion up to 7.6m in length into specified component parts.Bending - singular plane automated bending of aluminium sections and profiles in excess of 90 degrees, depending on section profile.

Sawing - Capalex has a range of saws that allow us to cut to the tolerances you require.

CNC Machining & Milling - we have a series of specialised CNC machines that enable simple to complex detailing of extruded products.

Punching - we have a range of single and multi-headed punching facilities suitable for various profile

sizes and lengths.

Conventional Drilling, Tapping, Milling & Turning - we often use conventional machines for one-offs and prototypes.

Deburring - enables us to remove burrs created during the sawing and machining processes.

You can find out more about our machining capabilities by visiting www.capalex.co.uk.

Powder Coating

The powder coating process is used to provide a durable and protective decorative finish to metals and a range of other materials. We typically employ our powder coating facilities for window systems, conservatory sections, hinges, lighting systems, office furniture, and curtain rails, but there are few limitations to the process. A wide range of finishes and colours are available, including metallic, glossy, clear and textured. Powder coating delivers a consistent finish that offers excellent protection against corrosion, chipping, marking and scratching. It is a high versatile process that can be applied to most metal components, including aluminium, brass, steel and zinc, on both internal and external surfaces.

Standard Sections

Capalex offers an outstanding range of standard aluminium sections which are made to order normally within two weeks. This includes channels, equal angles, unequal angles, tees, flat bars, round bars, square bars, hexagonal bars, round tubes, square tubes, rectangular tubes, J sections, Z sections, H Sections, bevel edge bars, half round bars, double & single feather edge bars, handles and trims, moulding caps and beads, and many more. For sizes and specifications, please head directly to the Capalex website.

Design

The Capalex design team are able to work with your engineers throughout the development process to produce an aluminium extrusion that meets the exact requirements of your application. Our state-of-the-art software enables us to read numerous file types, including .dxf, .dwg and Dolphin partmaster CAD/CAM .dra drawing files, so whether it’s a rough sketch or a complex electronic design, Capalex can help. If you would like to discuss your design requirements with the Capalex team, just give us a call on 01946 811771.

Longbed CNC Machining

Standard CNC machines usually have a bed size measuring up to one or possibly even two metres. The machining head with the cutter remains stationary while the bed moves around. Longbed CNC machines, on the other hand, clamp the component in place (usually long sections) while the cutting head moves in a 4 axis motion along its length, changing the tool where necessary. This allows parts such as window frames and shower cubicle sections to be machined without changing the clamp location. To find out more about our Longbed CNC machining capabilities, please get in touch with the Capalex team on 01946 811771.

Assembly

Capalex is extremely pleased to be able to offer full assembly and supply services to meet the project requirements of its customers. This includes detailed product assembly, testing, labelling and any other custom assembly requirements. An open and flexible approach enables us to offer a customer-focussed solution that is fast, efficient and effective. The ability to supply completely finished and packed assemblies makes Capalex a 'one stop shop' for an increasing number of manufacturers. We are already supplying many complex and demanding assemblies for customers in the petrochemical, retail and electronics industry.

Aluminium Alloys

Capalex is able to produce aluminium extrusions in a wide range of alloys, including those incorporating copper, manganese, silicon, magnesium, magnesium & silicon, and zinc & magnesium. The most commonly used alloys are within the 6000 and 7000 series, such as 6005A, 6060, 6061, 6063, 6063A, 6082, 7020 and 7075. These are used for a wide range of applications. Please visit www.capalex.co.uk if you would like to find out more.

Details

Info

| Registration Number: | 03218112 |

| VAT Number: | n/a |

| Registered at Companies House: | 28 June, 1996 (27 years and 11 months ago) |

| No of Employees: | n/a |

| Annual Turnover: | n/a |

| Importers: | |

| Exporters: | |

| Company Type: |

|

Opening Times

| Monday | 09:00 AM - 05:30 PM |

| Tuesday | 09:00 AM - 05:30 PM |

| Wednesday | 09:00 AM - 05:30 PM |

| Thursday | 09:00 AM - 05:30 PM |

| Friday | 09:00 AM - 05:30 PM |

| Saturday | Closed |

| Sunday | Closed |

Questions

Additional Information

Brand & Trade Names

- Capalex

Company Certifications

| ISO 9001:2015 - Quality management systems – Requirements |

Products & Services

Gallery

Financial Information

To view more detailed financial information for this company click here.

- Family Wealth Matters Ltd

- Cameron Estates Management Ltd

- Hayes Cs Ltd

- Community Matters Magazines Ltd

- Allendale Components

- ESSEX

- Graham, John (Dromore) Ltd

- Plastic Packaging

- Logical Trading Ltd

- John Chirnside & Sons Ltd

- Rentmyhome.co.uk Ltd

- Dual Fuel Boilers

- Gas Spring Struts

- Dip (England) Ltd

- Magnetic Actuators

- Mark Anthony (Dartford) Ltd

- Bmo Rep Asset Management Plc

- Crimping (Cereal and Pulse Processing) Products

- Raindrop Information Systems Ltd